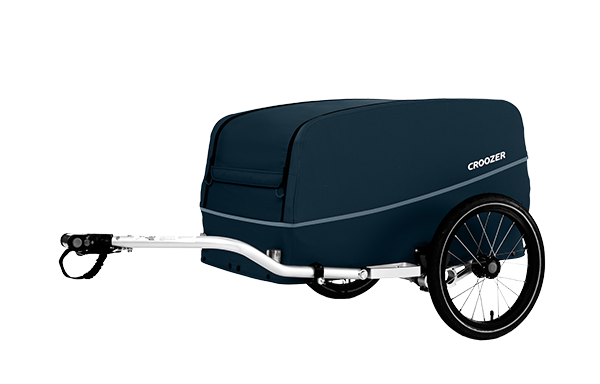

FROM US FOR YOU: DESIGNED AND DEVELOPED IN GERMANY

We at Croozer have been committed to sustainable family mobility since 1993. Our in-house product designers and engineers are also Croozer enthusiasts and therefore know exactly what types of features are most important for everyday use. In the development workshop at Croozer’s headquarters in Hürth, they tinker, tweak and test. Their aim: to develop outstanding trailers that enable you to get around in safety and comfort! So, what does the development process look like? We’ll be taking you on the journey with us: from concept to production.